Attention was first brought to the area for limestone quarrying due to the construction of the Bourne railway, When this was being created it revealed a 60ft thick seam of ironstone present under the limestone . During WW2 Stanton Ironworks & Co. Ltd. who were on site operating the limestone quarry looked at the possibility of mining the Northamptonshire ironstone. This lease had been acquired cheaply in the slump due to the war, it was for 2361 acres where the farmers would remain as tenants. In 1944 the drift was driven into the side of the limestone quarry entering beneath Mill Lane with a sweeping descent of 1 in 25. All output would be dispatched at the station via the “hoist”. One loco was attached with headlamps now to be used in the drift mine instead of in the limestone quarry, it would remain in here until it had to be replaced, spares were kept on the surface in wooden sheds. On December the 5th 1948 the BBC visited the mine !

The above image was taken in October 1956 .

Stewart and Lloyd in 1951 got the go ahead for ” Total extraction”. On 24th December 1953 they had been granted 1/3 of the permission they had asked for , this would cause large amounts of damage to the surface due to the pillar robbing operation, the whole of the surface would be dropping to the depth of the seam removed !. They were already getting 500k tones per annum and with this agreement for 5 headings to now commence pillar robbing the site would certainly double the output . Major work would also need to commence at the surface to deal with the larger output , a new tippler dock would be created and a loading station to change the ore into the standard gauge buck minster line.

The original adit

South Witham Limestone Pit (Stanton Ironworks Co. Ltd.), 1/2 m. WSW of South Witham. Looking NNW. Pit in Lincolnshire Limestone worked by Stanton Ironworks Co. Ltd. for use as a flux in their funaces. Adit is the entrance to the South Witham Ironstone Mine (Northampton Sand Ironstone). 1945 -BGS archive

A VIEW OF THE ORIGINAL HOIST

Eimco loaders would have loaded many of the tubs like the images above .

South Witham Limestone Pit (Stanton Ironworks Co. Ltd.), 1/2 m. WSW of South Witham. Looking SE. View of tubs loaded with limestone and of hoist for transferring stone onto rail. 1945 – . BGS archive

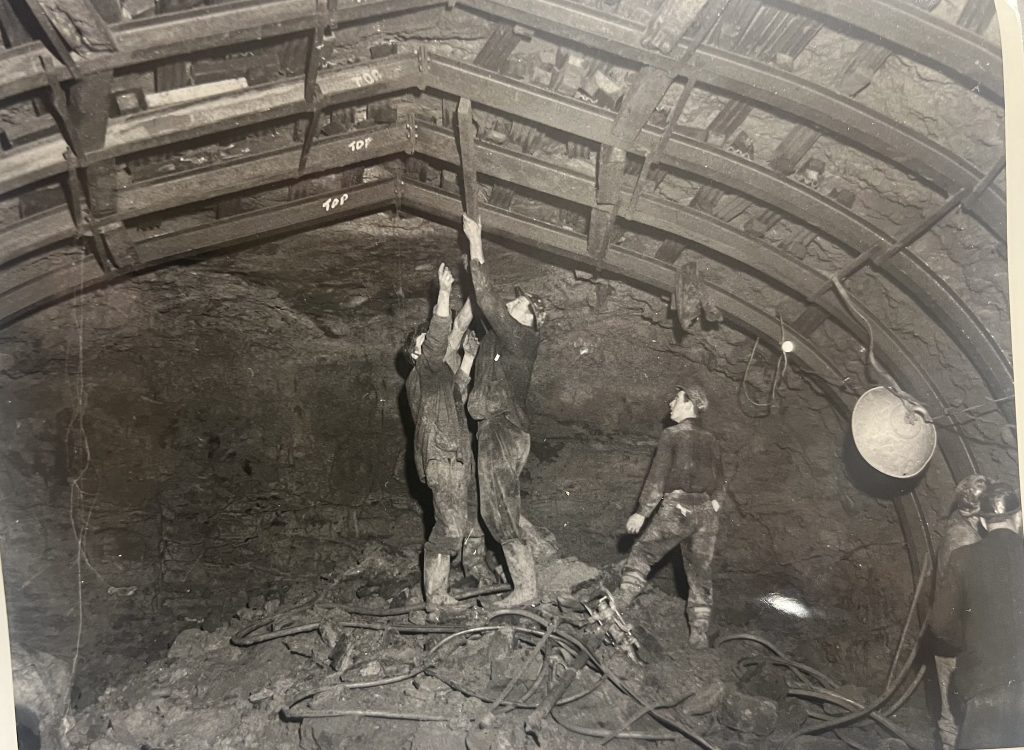

An entirely new mining complex was to be built on the north side “opposite side” of where the original adit was driven, this was on a different gradient also this was constructed 1 in 40. The adit would have steel ring arches with concrete inserts, it would measure 1600ft in length . The original adit would still be used for ventilation purposes , For this new adit to get completed teams would work from inside the mine and from the surface . During the modernisation 2 different gauge tramways were in use in the mine , the standard 2ft 6″ gauge then a larger 3ft 8″ gauge. This must of been a real head ache to deal with. Production continued to operate throughout this period. Once all was complete the old adit became the return airway . It was constructed and opened in 1957 as the plaque says .

Photo taken in January 2024 showing the welded shut door and the sealed adit .

1957 onwards –

The ring arches themselves are very impressive .

In 1958 the new operation came into play, the age of mechanical power and loading was here. Each loop of the narrow gauge now had to have a reversing line as law would not allow pushing of tubs. From the drift there were on each side 7 main galleries and from these side tunnels ran to the working faces. Here mechanical loaders filled “shuttle cars” that took the ore to the railhead where the load was transferred by an elevator to a mine car . A set of 8 mine cars had to be loaded then hauled out of the mine to a dead end , propelled over an automatic weigh-bridge, then taken up one at a time by a mechanical mule and hauled into a tippler , where the ore was discharged down a chute to a conveyor belt and thence to a 100 ton hopper over the standard gauge metals . Heavy chains dangling in the hopper helped smash the ore , the empty tubs were quickly remarshalled for re entering the mine .

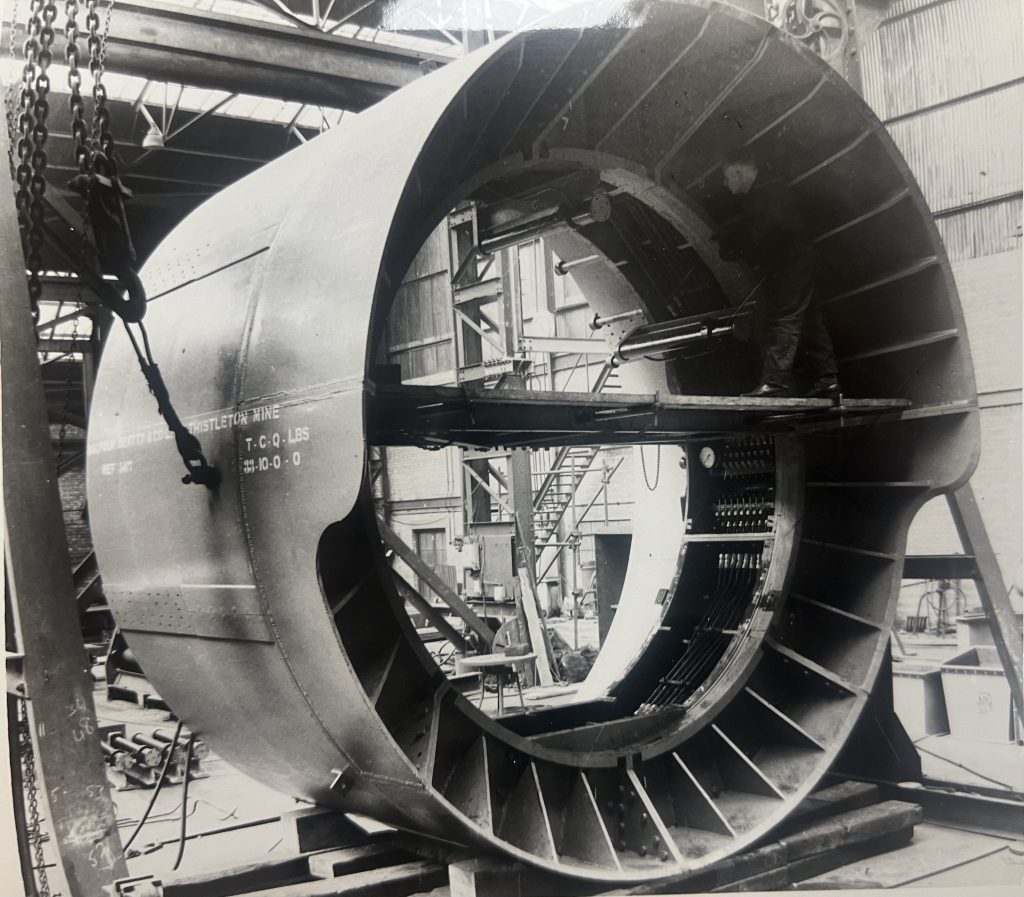

The mine was originally intended to have electric locos with overhead power cables , 2 were built and at work elsewhere in the UK. They were 221hp each. Thistleton ended up having 3 diesel locos which would all work at the same time later on in the mine as production in 1963 went up to 390,000 tonnes per annum. Another interesting note regarding transport is the listed details on the explosive waggon, it was bright yellow with letters painted on it in red.

Troubles started to arise due to wash outs regularly occurring in the mine, where large sections of ironstone was missing and water would pour in from the limestone above. A large amount of effort was put in to fix these issues , constant pumping was put into place . Due to water ingress the mine shuttle cars was also changed by a specially designed end tipping mine dumper, the diesel electric shuttle cars where 25ft long 8ft wide and carried 12 tonnes a time ! The new mine dumpers to replace these where 15ft 8″ long 8ft wide and carried 8 tonnes a time, due to issues exchanging onto the conveyor belt hand loading ended up being the best option.

The drilling machines by this date were very advanced .

The ventilation and dust extraction can be seen in the image above .

Due to larger draglines being developed, the cost of underground mining was its downfall. In 1964 Thistleton was put on a run down basis and 130 miners were given their 6 month notice. History says all track was lifted out of the mine & all locos sold off .

The two above photos were contributed to NVMSG by a G. Preston. They show the drift entrance , this clearly is still intake and has not been filled in under the surface road. Bats have been reported in the area so this entrance should not be sealed.

Possibly a image from when the mine first started operating .