A 1875 geological survey by a Mr John Judd says .

The Collyweston Slates have been dug over a considerable area in Sheet 64, old pits being traceable from Wothorp near Stamford to the western side of Collyweston, a distance of more than three miles. At the first of these places they are said, by tradition, to have been met with much nearer the surface than in the present workings, and this statement is confirmed by the geological relations of the beds in this neighbourhood. The valuable fissile character of the beds is merely a local accident; and in some directions the bed of stone has been followed and found to become non-fissile and in consequence worthless for roofing purposes. There is only a single bed of stone (the lowest limestone of the series) which is used for making roofing slates. This varies greatly in thickness, being often not more than 6 inches thick, but sometimes swelling out to 18 inches, and in rare cases to 3 feet; while, not unfrequently, the bed is altogether absent and its place represented by sand. Rounded mammillated surfaces, like the “pot-lids” of Stonesfield, abound in these beds.

The slates are worked either in open quarries or by drifts (locally called “fox-holes”) carried for a great distance under ground, in which the men work by the light of candles. The upper beds of rock are removed by means of blasting, but the slate rock itself cannot be thus worked,’ for though the blocks of slate rock when so removed appear to be quite uninjured, yet, when weathered, they are found to be completely shivered and consequently rapidly fall into fragments. The slate rock is therefore entirely quarried by means of wedges and picks, which, on account of the confined spaces in which they have to be used, are made single sided. The quarrying of the rock is facilitated by the very marked jointing of the beds, a set of master-joints traversing the rocks with a strike 40° W. of N. (magnetic), while another set of joints, less pronounced, intersect the beds nearly at right angles.

During the spring of the year the water in the pits rises so rapidly that it is impossible to get the slates out

The slates are usually dug during about six or eight weeks in December and January. The. blocks of stone are laid out on the grass, preferably in a horizontal position. It is necessary that the water of the quarry shall not evaporate before the blocks are frosted, and they are constantly kept watered, if necessary, until as late as March. The weather most favourable to the production of the slates is a rapid succession of sharp frosts and thaws. If the blocks are once allowed to become dry they lose their fissile qualities, and are said to bo “stocked.” Such blocks are broken up for road-metal, for which they afford a very good material. The limestone beds above the slate rock are burnt for lime.

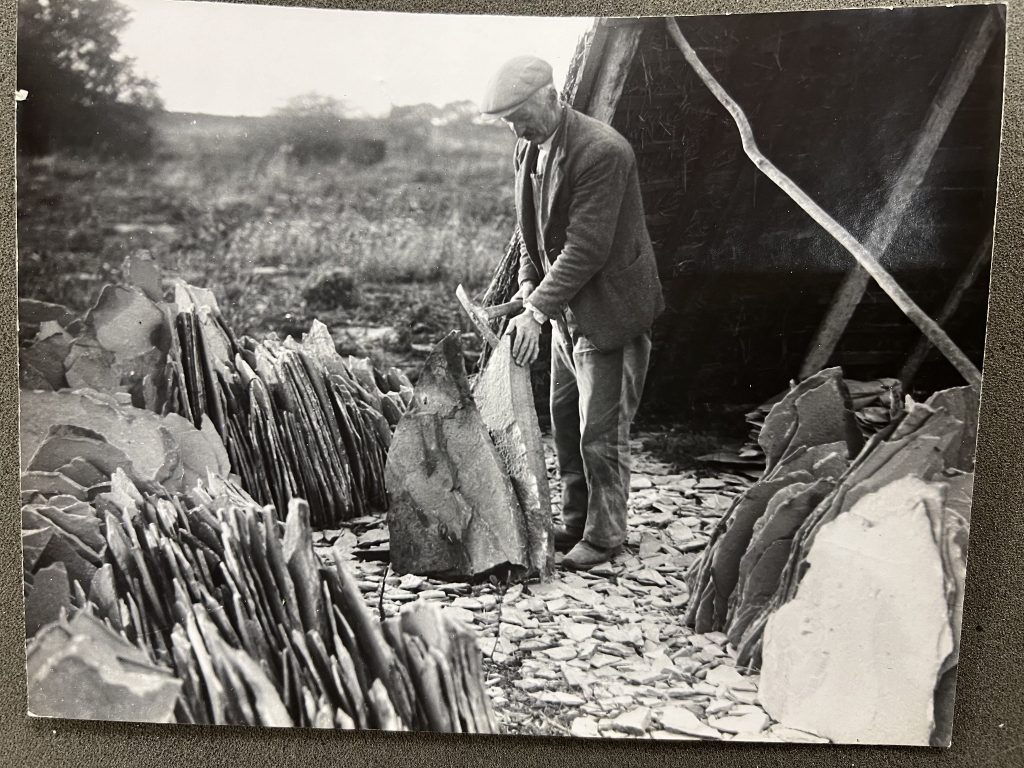

The slates are cleaved at any time after they are frosted. Three kinds of tools are used by the Collyweston slaters. The “cliving hammer,” a heavy hammer with broad chisel-edge for splitting up the frosted blocks. The “batting hammer” or “dressinghammer,” a lighter tool for trimming the surfaces of the slates and chipping them to the required form and size. The “bill and helve,” the former consisting of an old file sharpened and inserted into the latter in a very primitive manner. This tool is used for making the holes in the slates for the passage of the wooden pegs, by means of which the slates are fastened to the rafters of the roof. These holes are made by resting the slate on tho batting hammer and cutting the hole with the bill.

The slates are sold by the “thousand,” which is a stack usually containing about 700 slates of various sizes, the larger ones being usually placed on the outside of the stack. The slates when sold on tho spot fetch from 23s. to 45s. per thousand. Many of the Collyweston slaters accept contracts for slating, and go to various parts of England for the purpose of executing their contracts.

The land at Collyweston is generally held by slaters by copyhold, the slaters paying 6s. 8d. per ” pit” to tho lord of the manor (a “pit “is 16 square yards) with an extra charge of Is. 6d. per pit to the measurer. A few workings aro rented of the lord of the manor, the slaters paying 30s. per pit with an additional Is. 6d. for the measurer. These payments are made every year at the annual “slaters’ feast” held in January.

Tho manner in which the slates are placed on the roof is as follows:- -The largest are laid on nearest the Avail plate, and the size of tho slates is made gradually to diminish in approaching the ridge. The ridge itself is covered by tiles of a yellowish white tint, made at Whittlesea, and harmonising well in colour with the slates themselves. The larger slates are, in the ordinary way, fixed to the rafters of the roof by means of wooden pegs driven through a hole in the upper part of each slate. But roofs are often covered with small slates which are fixed by mortar.

http://www.stoneroof.org.uk/historic/Historic_Roofs/Collyweston_project.html

A image showing a passage way in a underground working at Colly Weston containing stacked deads . photo by Glynn Preston.

A unique roof support in a underground working at Colly Weston , photo by Glynn Preston

The freezing technique to separate the slate can be witnessed in the images above . Today we have to do an artificial freezing technique in large freezers. Used Colley Weston roofing slate ranges from £180-£250 a single square meter none fitted in the year 2024.