This page describes the general working method of the local ironstone mines. Practices changed over time, and were different from location to location, but this gives a good flavour.

Health and Saftey in the early years, definitely was not to today’s standards . Photo glass slide scan from Northamptonshire archive services .

Ore extraction

To extract iron ore, multiple holes are drilled into the rock using drills

Then the holes are filled with Ammonal, which is a high explosive.

The hole is plugged with a clay, and the contents rammed tight with a stemming rod. The rod is made of wood and copper to prevent any sparks being generated.

Detonators are fitted, then the whole lot is set off.

This will generate a pile of iron ore of varying sizes. The ore is destined for the furnaces, where it is heated. For this to work properly air must be able to get through the ore, which means that the very small ore is not used.

The ore is sieved either with a sieve or a fork:

and loaded into tipping wagons for removal to the furnaces.

The waste small ore is just dumped along the side of existing tunnels.

Transport

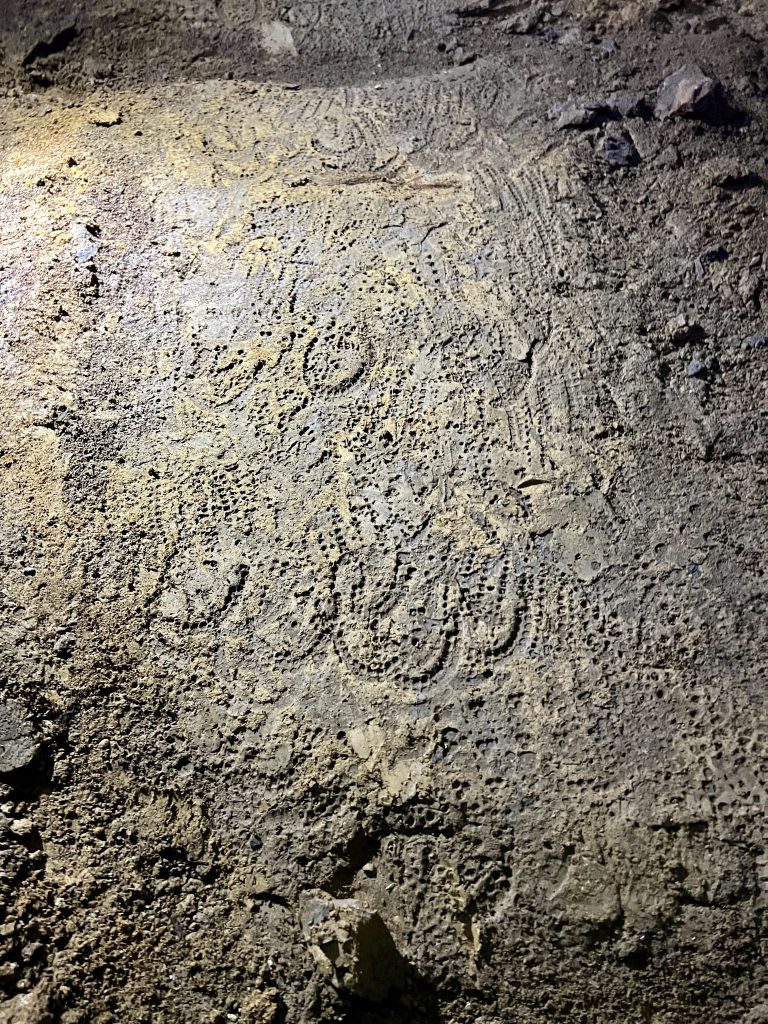

Men could travel around the mine on foot (or more precisely, in hobnail boots).

Some mines had diesel or electric locomotives, others were horse powered.

Narrow gauge rail track was laid to the working face

and connected via branch lines

to the main haulage routes out of the mine.

Lighting

Carbide was used as the main form of lighting. The men would have a carbide lamp, which required carbide fuel and water to generate acetylene.

The carbide came in large drums

The waste was dumped in an old heading.

Ventilation

Ventilation in an iron mine is critically important. When the ventilation system has stopped working, the oxygen and carbon dioxide levels can become lethal. This image was taken outside an iron mine which was ‘breathing out’ because of falling atmospheric pressure. It is for this reason that the mines are sealed.

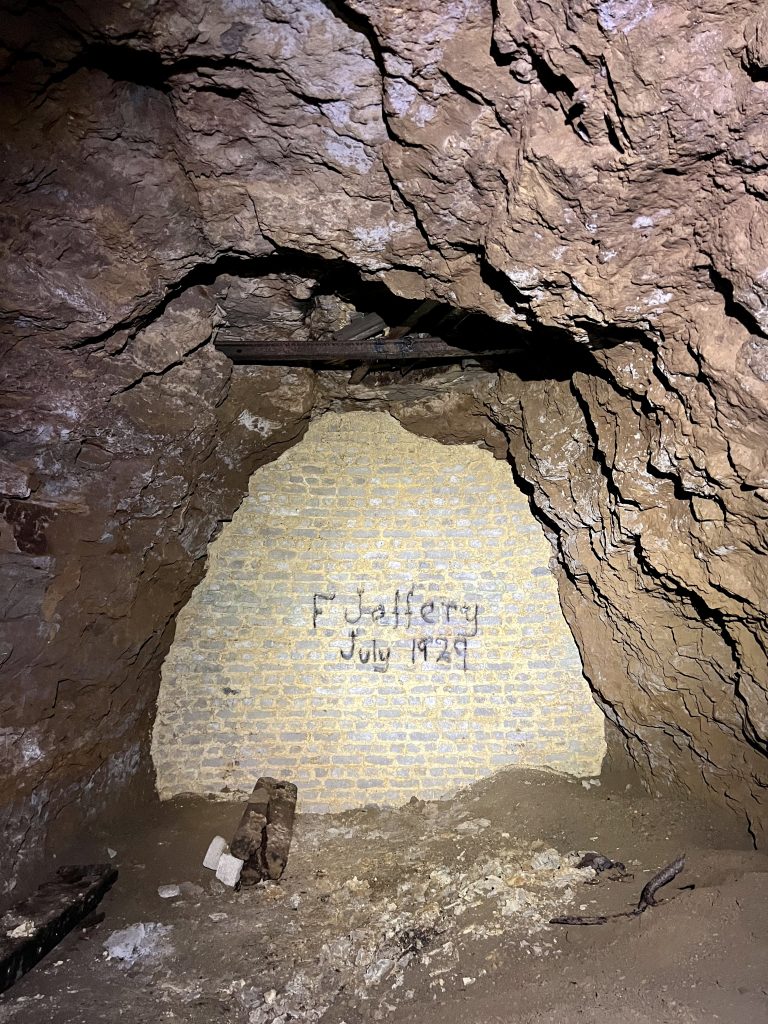

When operating, air would be forced around the mine. Sometimes by lighting a fire at one entrance and drawing air through, other times with a large fan. To ensure the air travels around the mine in the correct direction, levels can be completely stopped up

or a temporary barrier (brattice) added.

Miscellaneous

Back in the 1930’s, smoking was not seen as dangerous, and it was still allowed in the workplace.

Perhaps beer was also acceptable underground.

Areas of work were marked by painting reference numbers on the wall in white lead paint.