The beginning – the north

Iron ore has been known of around the Church Mine North area for a long time because of Harpers Brook. In Harpers Brook water has washed away all the surface soil and clay exposing the iron ore bed. We don’t know if this was how they first discovered the ore bed, which led to the iron ore surface mine at Marshes Pit. Even though Church North was the last mine to start producing iron ore in the Slipton ore field, its roots started fairly early on with the usual surface mine period first. The surface mine was called Marshes pit which started producing ganister in 1896. This was north east from Islip furnaces and had its own direct tramway which was meant to be a pleasurably journey back in its day, the old timers its said laid this track to an exceptionally high standard. Marshes pit in the early days was a separate venture to the other surface mines and mines, solely working for ganister.

By 1920 they were looking at producing iron ore and started driving a heading for Church North mine. A brick built exterior stable was built for the first horse called Jack, this having a tin roof. Eight men were employed at this point; it is believed they worked just 1 shift. A managers office and miners mess room are also listed but no further details have been archived .

Every morning young lads would collect Jack from the stables and groom him, he then would be taken to his masters inside the mine at the working face. There were very strict rules that the horses were not allowed to gallop, also the wagons could not be over loaded, any miner breaking these rules would be fined 6d, payment was to be made to Kettering General Hospital.

1923 was Church Norths first year of iron ore output, this date matches the survey as the first date on any passage is down for 1925. Church North played a very important role for the first 10 years of its life, it had 2 adits and both are listed as a decent size which a horse could easily enter, the roof has regular track for support with corrugated iron sheets to keep water from falling down onto the horse or miner. One rare extra feature was a half round guttering system which was attached to the sheets. Presumably this adit must have been wet, this captured water off the tin sheets and transported it into a down pipe, from here it went into fissures in the rock.

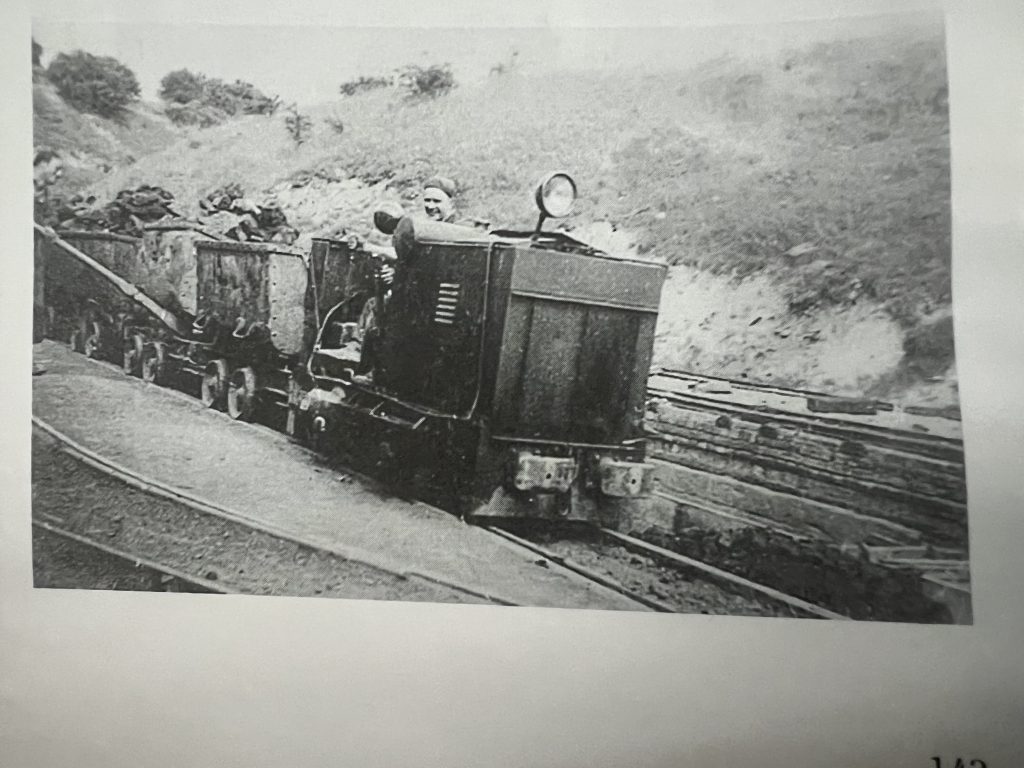

Outside in Marshes pit, two sunken tippler docks are located of a large size, it is believed that even the first wagons used would have been of this design. In 1930 we know locomotives were introduced into Church Mine. Some passages (approx 1 out of 10 in the northern region) are notably lower, is this to accommodate for the loco collecting ore production from Marshes Pit ? Who knows. Church North continued its output till January 1933, from this date how the mine exported its ore would change.

Production from Marshes Pit would carry on until 1947 for iron ore & ganister . The date the grilles were installed onto Church North adits is unknown but any ore/ganister produced went through the mine and out the South.

The fate for Church North was not a surprise. Rows of lorries would bring in sub soil and start filling Marshes Pit. These created a ramp all the way to the adits, now the lorries could reach the adits and their fate was clear. Both adits would be completely covered.

Here we have a photo taken of inside church mine by Glynn Preston . It shows the pillar and stall workings with roof supports , drainage channels and a make shift bridge

The South / Church Pit

Details regarding Church South are very scarce, regarding the early days nothing at all has been noted. It is obvious that Church South was driven towards Church North as north was driving towards south. Both mining techniques are the same style, but with hard studying of the surveys one can see the passage style does have a slight change, where the suspected join has been made.

When the locos were introduced to the mine, 5 locomotives were now working in the region. One of the locos working in Church was a Ruston & Hornby 33/40hp 3 cylinder engine, this must have been a splendid sight to watch. They even worked to a strict time table with keepers on all the level crossings. Ore leaving Church South was by horse or by loco, horses were used until the very last day, this then went straight to the tippler dock. Details of the Church South pit in the early years again haven’t been saved but it is described as “brick piers” where the tubs was emptied by handles for tipping them into the 3ft gauge wagons. With the introduction of the locos came the increase in production, output immediately doubled and ore was being sent to Corby and Wellingborough.

1940.

During the war period more ore was needed. A new tippler dock was added into Church Pit, this facing to the East of the old tippler dock. Because of this a reversing triangle was added for wagons to reverse into to then go up onto the tippler dock. Around this time Church Mine adopted compressed air for drilling and chiseling, this was sent from a compressor building at Islip furnaces which is a long way to lay the hose. The hose was laid along the track to Church Pit, then it went into the mine. It is suspected there must have been multiple holding tanks for the compressed air inside the mine and possibly in Church Pit itself, with multiple miners using these tools a large build up of pressure would need to be stored at all times.

In 1940 we know 80 miners were working and they had 12 horses, these miners was working in 2 shifts. We know the early days was 7-3 for Church North, maybe now it was 6-2 then 2-10 this is only a guess as again these details haven’t been recorded sadly. We know the miners worked in pairs, one gets the stone and one loads the stone. In 1942 on the 6th of October Islip furnaces shut down, the need for foundry iron had diminished. Church continued to produce ore until 22nd august 1947. After the closure 2 locos went back to Buckminster for refurbishment. Two were supposedly scrapped and the other remained on site until 1953, it’s believed then it was also scrapped. All the narrow gauge line was also lifted and scrapped. Church South adits are listed as being “boarded” up .

The fate for Church South in the end is different to all the other mines and surface mines locally. It was completely filled with household rubbish in the sixties then landscaped over. In 1969 a local history group visited the site and said the adits could just be viewed but rubbish was getting close to covering them. Now it’s a field for livestock to graze, all traces are gone.

The technique

The mining technique in Church Mine was pillar and stall. This would allow the mining company to remove 50% of the workable ore without causing any subsidence, in theory “even though some happened“.

Headings were driven roughly 13ft wide 50 degrees to each other, this is to give a diamond shaped pillar with sides which are 2 1/2 to 3 chains long. Through each individual pillar 8-13 individual pillar heads are driven into the pillar these again are 13ft wide with roughly a 18” wall in-between each other. This is the basic mining method for the removal of iron ore, this will change depending on tramway routes -faults and other areas located inside the mine.

A row of tippler wagons leaving church south April 1946 note the handles on the side of the tubs for tipping into the 3ft gauge line. Photo from the BGS archive.

We have received a account on wages/ working conditions from 1930 –

The rates of pay in the mines vary considerably, being based on difficulty of mining, so that, for example . Willow Close and Church Mine North differ and even in the same mine rates will differ. In is all done on piece work and a miner earns on average 9/- per day though some may earn 12/- and a helper earns 7/- per day. Much depends on individuals however . The daily hours worked where 8 1/2 hours underground , 7-3 though on piece work they was not strictly followed. Workers where expected to fill 7 tubs a day (2) man gang this works out 6 ton per worker per shift.

Church Mine had 18 workers in Church South, 9 workers in Church North .

Photo by Greg Evans